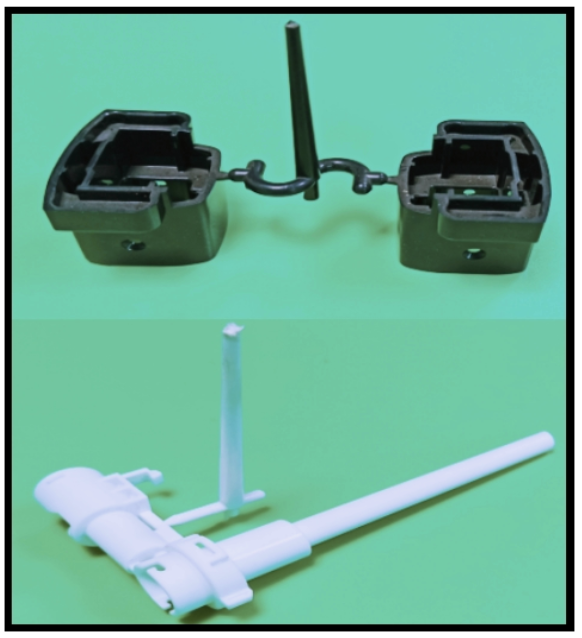

Injection molding is a process to check mold design and mold making, if any NG is from design and making, we can find from injection. Normally, we make mold T1 to check mold quality, we need to follow final production parameters to check from mold movements, such as ejector pins, lifters, slider's movements, the most important we need to check carefully for the plastic parts, inside and outside, visible or not visible, to find out all the issues then fix as the quality control, this is the work and meaning from mold T1 and fixing.